PROFESSIONAL PIGMENT MANUFACTURER

|

Brand

|

Fineland Chem

|

|

Color Index

|

Pigment Yellow 13

|

|

Color Index No

|

21100

|

|

CAS No

|

5102-83-0

|

|

EC No

|

225-822-9

|

|

Chemical Group

|

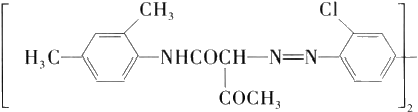

Disazo

|

| Chemical Formula | C₃₆H₃₄Cl₂N₆O₄ |

Pigment Yellow 13 (PY13) is a disazo organic pigment widely used in printing inks, coatings, and general-purpose plastics.

It is known for its bright yellow shade, good color strength, and cost-effective performance, making it a common choice for large-volume industrial applications.

Due to its moderate heat resistance, Pigment Yellow 13 is mainly applied in ink and coating systems and is not recommended for high-temperature engineering plastics.

PY13 – DuraPrint®3122 ⬇️TDS

This is a greenish yellow shade pigment with semi-opaque characteristics, recommended for water-based systems including mill base, textile printing pigments, as well as plastics, coatings, and paints, offering high color strength and stable dispersion performance across various applications.

PY13 – DuraPrint®S6133 ⬇️TDS

This is a good transparent yellow pigment specifically designed for nitrocellulose (NC) ink systems, delivering clean shade and stable performance.

PY13 – DuraPlast®3122P ⬇️TDS

This is a reddish-yellow pigment with semi-transparent properties and good color strength, suitable for plastic applications.

|

Test Item

|

Specification

|

|

Density (g/cm3 )

|

1.5-1.73

|

|

Specific Surface Area(m2/g)

|

10-62

|

|

Oil Absorption(g/100g)

|

30-45

|

|

PH Value

|

6-8

|

|

Moisture Content (%)

|

≤2

|

|

Total impurities(ppm)

|

≤600

|

| Heat Resistance (℃) | 180 | Alkali Resistance (1-5) | 4 |

| Light Resistance (Full Shade, 1-8) | 5 | Migration Resistance(1-5) | 3 |

| Light (Reduced tinting, 1-8) | 4 | Ethyl Acetate (1-5) | 4 |

| Weather Resistance (1-5) | 4 | Ethanol (1-5) | 3 |

| Acid Resistance (1-5) | 4 | MEK (1-5) | 3 |

Pigment Yellow 13 is widely used in printing inks, coatings, and general-purpose plastics, where bright color and cost efficiency are required.

In the printing industry, it is commonly applied in solvent-based and water-based inks, especially for packaging and publication printing.

In coatings, Pigment Yellow 13 is suitable for decorative paints and industrial coatings that do not require high-temperature processing.

For plastics, it is mainly used in general plastic coloring and masterbatch applications with moderate thermal requirements.

Pigment Yellow 13 offers a bright yellow shade with good color strength, making it suitable for applications where visual impact is important.

It shows good dispersion performance in ink and coating systems, contributing to stable color development during processing.

The pigment provides moderate heat resistance, which meets the requirements of most general plastics and coating applications.

Its cost-effective performance makes it a preferred choice for large-volume industrial uses, particularly in inks and decorative coatings.

1. Excellent Migration Resistance

Pigment Yellow 13 boasts outstanding migration resistance, ensuring stable and durable color performance in various products. Its low migration tendency is especially beneficial in products where long-lasting color stability is essential.

2.Excellent Lightfastness and Multi-Media Stability

Pigment Yellow 13 exhibits excellent lightfastness in full shades, effectively resisting fading caused by light exposure. It also maintains stable performance across various media, ensuring outstanding reliability and durability in diverse application environments.

1. Moderate Heat Resistance

Pigment Yellow 13 has moderate heat resistance, which limits its suitability for high-temperature engineering plastics or processing conditions involving prolonged heat exposure.

2. Limited Suitability for High-Durability Applications

In applications requiring higher thermal stability, improved weather resistance, or long-term outdoor durability, Pigment Yellow 13 may not meet performance expectations, and alternative pigments with enhanced properties should be considered.

When sourcing Pigment Yellow 13, buyers are advised to clearly specify their end-use application, such as printing inks, coatings, or plastics.

Key factors to confirm include heat resistance requirements, dispersion method, and color shade expectations.

For export-oriented projects, buyers should also clarify regulatory and compliance requirements, as well as batch consistency expectations.

Providing detailed application information helps pigment manufacturers recommend the most suitable grade and reduces the risk of performance mismatch.

| Pigment Yellow 13 | C.I. Pigment Yellow 13 | C.I. 21100 | Organic Pigment Yellow 13 |

| Diarylide Yellow | Diarylide Yellow AAMX | Diarylide Yellow AAA | Permanent Yellow GR |

| Benzidine Yellow GR | Benzidine Yellow G | Benzidine Yellow GRX | Benzidine Lacquer Yellow G |

| Helioyellow GW | Rangoon Yellow | Irgalite Yellow BO | Tertropigment PGR |

| Hostasin Yellow GR | Irgalite Yellow B3L | Lionol Yellow FG-1310 | Novofil Yellow A-GR |

| Permanent Yellow B3L | Pigment Yellow MH | ISOL Benzidine Yellow G 2537 | Benzidin-Yellow |

| Dominion Yellow AAMX (DCC-1232, 1235, 1237, 1239) | Dominion Yellow AAA (DCC-1205, 1213, 1226, 1227) |

Fineland Chem is a B2B manufacturer and exporter of industrial organic pigments, supplying Pigment Yellow 13 for applications in inks, coatings, and plastics.

The product is manufactured under controlled quality systems to ensure stable performance and batch-to-batch consistency.

With experience in international pigment supply, Fineland Chem supports customers with technical communication and application-oriented pigment solutions.

● 25KG Kraft Bag, 400kg/500kg Carton Box

● Lead Time: Normally around 15 days after signed contract.

1. Is Pigment Yellow 13 suitable for plastic masterbatch applications?

Pigment Yellow 13 can be used in general-purpose plastic masterbatch applications with moderate processing temperatures, but it is not recommended for high-temperature engineering plastics.

2. What are the main applications of Pigment Yellow 13?

Pigment Yellow 13 is mainly used in printing inks, decorative and industrial coatings, and general plastics where bright yellow color and cost efficiency are required.

3. Does Pigment Yellow 13 work well in water-based inks?

Yes, Pigment Yellow 13 is commonly used in both solvent-based and water-based ink systems, especially for packaging and publication printing.

4. What are common alternatives to Pigment Yellow 13?

Depending on performance requirements, alternatives may include pigments with higher heat resistance or improved durability, such as Pigment Yellow 12 or other high-performance yellow pigments.

Copyright © 2024 Fineland Chem Co., Ltd /HangZhou FanCheng Chemical Co., Ltd.