Enhancing Knowledge for Sales, Procurement, and Technical Teams

Fineland Chem conducted a comprehensive training session on petroleum resin production and its applications. This session was aimed at sales, procurement, and technical (quality control) teams, providing them with a deeper understanding of petroleum resins, their manufacturing processes, and their wide range of applications. The purpose of this training was to enhance product knowledge and improve the customer experience by helping employees better understand key product features, performance characteristics, and use cases.

This training was an essential part of Fineland Chem’s ongoing commitment to employee development, particularly for new hires who will need to build expertise in petroleum resins, C5 hydrocarbon resin, and its varied applications in industries such as road marking paints and coatings.

Understanding Petroleum Resins: Production Process and Types

Petroleum resins are a class of hydrocarbon resins derived from the distillation of petroleum. They are produced through the polymerization process, which involves the chemical reaction of light hydrocarbons, typically sourced from C5 or C9 fractions. Petroleum resins are commonly classified into C5 resins, C9 resins, and C5/C9 resins, depending on the molecular structure and the types of raw materials used in their production.

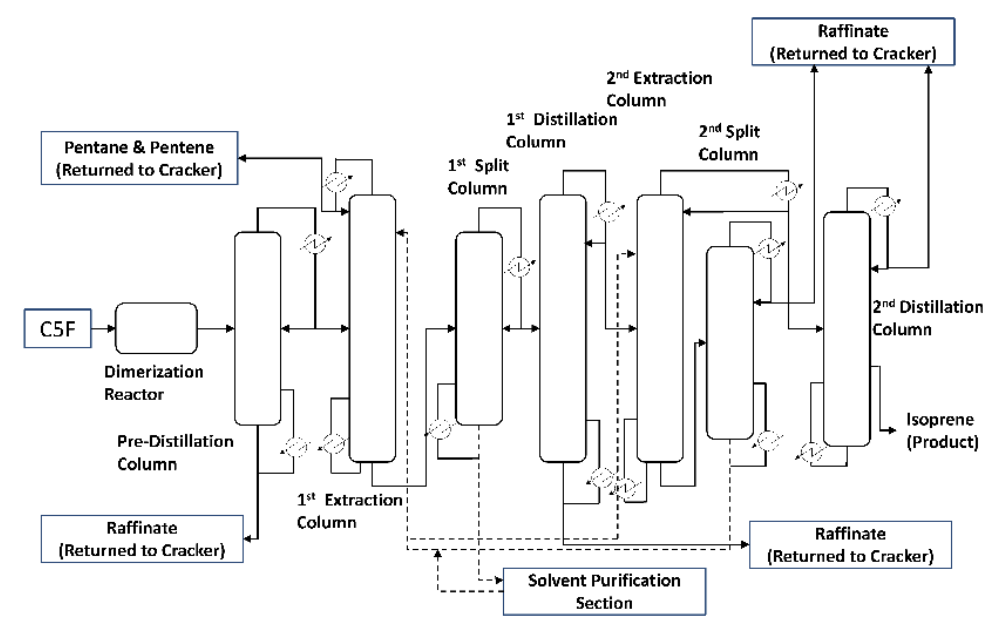

During the training, the process of C5 petroleum resin production was discussed in detail. This includes the polymerization of C5 hydrocarbons, which leads to the formation of resins with different characteristics like softening point, viscosity, and adhesion properties. C5 resins are particularly useful in a variety of applications, including adhesives, coatings, and road marking paints, due to their excellent tackiness and good heat resistance.

Understanding the production methods and the basic structure of petroleum resins is vital for all departments to better guide customers in choosing the right resin for their applications. For example, C5 resins have lower molecular weights compared to C9 resins, which makes them more fluid and suitable for use in pressure-sensitive adhesives and paints.

Applications of Petroleum Resins in Different Industries

Petroleum resins are used extensively across various industries. In road marking paints, petroleum resins play a critical role in enhancing adhesion to road surfaces, weatherability, and durability. The resins are carefully selected based on their ability to form strong bonds with the pavement and resist wear from weather, traffic, and environmental factors. As a result, C5 resins are often preferred in road marking paints due to their excellent tackiness and fast-drying properties.

Road marking paints require resins that offer high durability and visibility. During the training session, participants gained insights into how C5 resins are formulated with pigments and solvents to create road marking paints that maintain long-lasting color, even under harsh conditions. In addition, the flexibility and resilience of these resins contribute to the paint’s ability to withstand vehicle traffic and extreme weather. For more details on how C5 resins are used in this application, visit our road marking paints page.

Beyond road marking paints, petroleum resins are also critical in industries such as adhesives, coatings, and inks, where their high bonding strength and low volatility are highly valued. In adhesives, petroleum resins provide tackiness and high adhesion at room temperature, which are essential for making strong bonds in products like pressure-sensitive tapes and labels.

Quality Control and Procurement Considerations

In this training, we also highlighted the role of procurement and technical teams in selecting and sourcing the right petroleum resins for various applications. The quality control process involves testing for softening points, viscosity, and adhesion properties to ensure the resins meet industry standards. Teams learned how to evaluate the performance characteristics of each resin type and understand their suitability for specific end-use applications.

For example, C5 resins are selected for their low viscosity and good solubility in solvents, while C9 resins are better for applications requiring higher heat resistance. Sales teams are now better equipped to understand these technical specifications and help customers select the best resins for their needs.

Moving Forward: Continuous Learning and Professional Development

The petroleum resin training session marks another step in Fineland Chem’s commitment to professional development. As a company dedicated to offering high-quality resin solutions, we ensure our teams are equipped with the knowledge and skills needed to provide expert advice and technical support to customers.

The session was particularly beneficial for new employees as it provided a strong foundation in understanding petroleum resins and their applications, ensuring that they are ready to contribute effectively to customer interactions and product recommendations.

Fineland Chem remains focused on advancing the technical expertise of its team to stay at the forefront of the industry, delivering the most reliable and innovative products to customers worldwide. For further exploration of C5 resins and their applications, visit our C5 hydrocarbon resin page.