PROFESSIONAL PIGMENT MANUFACTURER

Main Technical Data

| Chemical Composition | Content | Physical Property | Parameter |

| ZrO₂ | 94.8±0.5% | Density | >6.04g/cm³ |

| Y₂O₃ | 5.2±0.5% | Bulk Density | 3.6-3.8g/cm³ |

| Compressive Strength | >75N(φ0.35mm) >350N(φ0.65mm) | ||

| Vickers-hardness | >1280 HV | ||

| Self Wearing-rate | <2.0 ppm/h | ||

| Cross-section | Uniform and dense | ||

| Roundness | >0.97 |

JZ95 Zirconia Beads are high-purity grinding media manufactured by Zhejiang Jinkun Sili Ceramic Beads Co., Ltd., a Sino-German joint venture established by Zhejiang Jinkun Zirconia Industry and the German company Sigmund Lindner GmbH. With internationally recognized German production technology and strict quality management, the company delivers world-class zirconia beads widely used in high-precision grinding and dispersion applications.

As an official authorized distributor, Fineland Chem provides genuine Jinkun SiLi zirconia beads directly from the manufacturer. The JZ95 series features outstanding roundness, smooth surface, high density (>6.04 g/cm³), excellent hardness (~1280 HV), and an exceptionally low wear rate (<2.0 ppm/h). These properties, combined with strong impact resistance and superior chemical stability, ensure high grinding efficiency and long service life—making JZ95 ideal for battery materials, advanced ceramics, titanium dioxide, pigments, inks, dyes, coatings, electronic materials, and other industrial sectors.

Backed by Sino-German technical collaboration and continuous R&D investment, Jinkun Sili Ceramic Beads Co., Ltd. has earned a strong global reputation, supplying well-known customers across Europe, the United States, and Asia. The JZ95 zirconia beads represent the company’s commitment to high performance, reliability, and long-term value for industrial grinding processes.

To recommend the most suitable bead size and type, we will need information about your sand mill, including the chamber size, internal structure, screen size, and the particle size you plan to grind. The table below shows the bead sizes we offer.

| Φ0.03 | Φ0.05 | Φ0.1 | Φ0.2 | Φ0.3 | Φ0.4 |

| Φ0.5 | Φ0.6 | Φ0.7 | Φ0.8 | Φ0.9 | Φ0.9-1.0 |

| Φ0.9-1.1 | Φ1.0-1.2 | Φ1.2-1.4 | Φ1.4-1.6 | Φ1.6-1.8 | Φ1.8-2.0 |

| Φ2.0-2.2 | Φ2.2-2.5 | Φ2.5-2.8 | Φ2.8-3.2 |

Remark: can be customized for clients

1. Good roundness,smooth surface,brightness,high density,high strength,inertia and hardness,perfect grindingmedium.

2. Good stability,strong acid resistance andalkaliproof.

3. Have excellent toughness,strength,impact resistance,not broken.

4. Minimum of wear and tear on equipments and best grindingmedia.

We ensure stable quality from the source because our zirconia powder is entirely self-produced, giving us full control over raw material consistency and purity. Our beads are manufactured using an advanced automated dripping process, which provides a highly compact internal structure and superior density. With stable raw materials and a stable production process, every batch maintains excellent uniformity, and each bead delivers the same high quality, ensuring reliable performance in demanding grinding applications.

| List of products | Product number | Specification | Usage |

| Monoclinic powder | JK-0Y-Q | High pure powder, after jet-steamed process | |

| Tetragonal ultra-fine powder | JK-3Y-Q | 3mol%Y203 stabilizer, without binder, after jet-steamed process | |

| Tetragonal spray dried powder | JK-3Y-Z JK-3Y-ZN |

3mol%Y203 stabilizer, added with binder and lubricant (No binder in JK-3Y-ZN) | |

| Zirconia powder for NCM battery material | JK-NCM-L JK-NCM-H |

Produced by Germany Technology Low Magnetic Content | to improve the electrical properties of NCM battery material |

| Zirconia powder for solid electrolyte | JK-Sol | Produced by Germany Technology, Low Magnetic Content | |

| Zirconium Hydroxide for battery material | JK-OH | Produced by Germany Technology Low Magnetic Content | to improve the electrical properties of NCM battery material |

| Ytrria Stabalized Zirconia for battery material | JK-YZ | Produced by Germany Technology, Low Magnetic Content | |

| Cubic ultra-fine powder | JK-8Y-Q | 8mol%Y203 stabilizer, after jet-steamed process | can be used in making sensitive unit and solid oxide fuel cel,ect. |

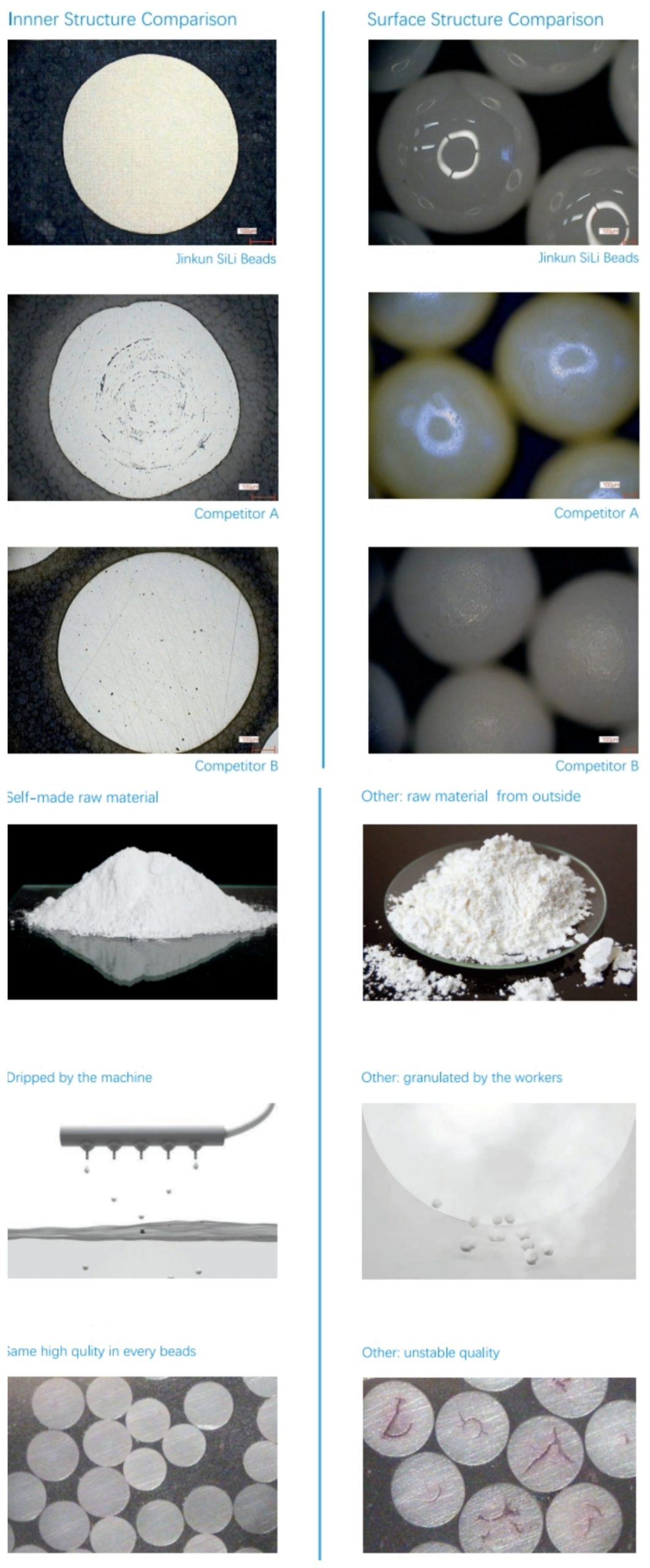

Jinkun SiLi zirconia beads feature a highly compact and uniform internal structure, with no visible pores or defects. This dense microstructure ensures superior mechanical strength, excellent wear resistance, and a long service life, even during high-energy grinding.

In contrast, beads from other manufacturers often exhibit obvious voids, cracks, and uneven density, leading to breakage, inconsistent grinding performance, and higher contamination in the final product.

The surface of Jinkun SiLi beads is smooth, bright, and uniformly rounded, minimizing friction inside the mill and reducing equipment wear. This smooth surface ensures more stable grinding efficiency and helps prevent bead fracture.

Beads from other manufacturers, however, often have rough surfaces, visible defects, and irregular textures, which cause grinding instability, generate impurities, and shorten bead lifespan.

Jinkun SiLi zirconia beads are made using our self-produced zirconia powder, ensuring consistent purity and uniform quality of raw materials. This guarantees that every bead within a batch maintains the same high standards, resulting in reliable and consistent grinding performance.

In comparison, other manufacturers rely on purchased zirconia powder, which often varies in composition and purity, leading to inconsistent bead quality across batches.

Our fully automated dripping process ensures each bead is formed under controlled conditions, resulting in highly uniform density, consistent size, and smooth microstructure. This precision-controlled manufacturing method contributes to exceptional bead stability.

On the other hand, beads from other manufacturers often undergo manual or semi-manual granulation processes, leading to inconsistent bead shapes, density, and internal structure, which in turn results in poor stability and unreliable performance.

At Jinkun SiLi, every bead in the same batch maintains uniform quality, reducing the likelihood of defects and ensuring consistent grinding results.

In contrast, competitors’ beads are more prone to defects, breakage, and irregular grinding performance, increasing the risk of contamination and reducing milling efficiency.

Our zirconia beads are widely used in high-end coating and ink systems, especially in processes requiring high grinding efficiency and excellent dispersion performance. They are popular in gravure inks, UV inks, inkjet inks, repair coatings, and other premium paints and coatings that demand superior fineness, low contamination, and stable particle size distribution.

Printing Ink: Discover high-performance ink pigments for various printing technologies including water-based, solvent-based, offset, inkjet, UV curing, and decorative applications. More Details

Paint and Coating: Explore a wide range of coating pigments tailored for paints, oils, automotive finishes, industrial applications, concrete, cement, and ceramics. More Details

Plastic and Masterbatch: Browse a comprehensive selection of plastic pigments designed for PE, PVC, EVA, rubber, and a variety of engineering plastics. More Details

Special Use: Find specialized pigments offering unique effects and functionalities for textiles, resins, glazes, metallic finishes, fluorescence, and anti-corrosion needs. More Details

Printing Ink: Discover high-performance ink pigments for various printing technologies including water-based, solvent-based, offset, inkjet, UV curing, and decorative applications. More Details

Paint and Coating: Explore a wide range of coating pigments tailored for paints, oils, automotive finishes, industrial applications, concrete, cement, and ceramics. More Details

Plastic: Browse a comprehensive selection of plastic pigments designed for PE, PVC, EVA, rubber, and a variety of engineering plastics. More Details

Special Applications: Find specialized pigments offering unique effects and functionalities for textiles, resins, glazes, metallic finishes, fluorescence, and anti-corrosion needs. More Details

● 25KG Kraft Bag, 400kg/500kg Carton Box

● Lead Time: Normally around 15 days after signed contract.

Copyright © 2024 Fineland Chem Co., Ltd /HangZhou FanCheng Chemical Co., Ltd.