Introduction

Selecting the right industrial pigment is a crucial step in developing high-quality coatings and plastic products. Pigments do much more than add color—they influence opacity, weather resistance, chemical durability, gloss, and even processing stability. The wrong pigment choice can lead to fading, poor dispersion, or surface defects, while the right one enhances both performance and aesthetic appeal.

In today’s global market, industries such as automotive, construction, packaging, and consumer goods demand consistent, cost-effective, and environmentally compliant pigments. Understanding pigment types, properties, and performance requirements will help you make informed decisions tailored to your application needs.

Understanding Industrial Pigments

Industrial pigments are finely ground, insoluble colorants that impart color through dispersion rather than dissolution. Unlike dyes, pigments do not chemically bond with the material—they remain suspended in the medium, providing long-term color stability and resistance to light, heat, and chemicals.

Pigments used in coatings and plastics can be organic or inorganic, each offering unique advantages depending on the desired performance characteristics.

Organic vs. Inorganic Pigments

Organic Pigments: Brightness and Transparency

Organic pigments are carbon-based compounds known for their vivid, high-chroma colors. They are often used when brightness and color intensity are priorities—such as in packaging films, decorative coatings, and consumer products.

Common examples include:

-

Phthalocyanine pigments (blue and green hues)

-

Azo pigments (yellow, orange, and red shades)

-

Quinacridone and perylene pigments (deep red to violet)

Advantages:

-

Brilliant color strength

-

Excellent transparency (ideal for plastics)

-

Wide range of shades and effects

Limitations:

-

Lower heat and chemical resistance compared to inorganics

-

May fade faster under UV exposure without stabilizers

Inorganic Pigments: Durability and Stability

Inorganic pigments are mineral-based and are prized for their exceptional weather, heat, and chemical resistance. They are ideal for outdoor coatings, industrial equipment, and high-temperature plastic processing.

Common types include:

-

Titanium dioxide (TiO₂) – the most widely used white pigment

-

Iron oxides – earthy tones like red, yellow, and brown

-

Chromium oxide green – excellent UV and heat stability

-

Ultramarine blue – stable under alkaline conditions

Advantages:

-

High opacity and covering power

-

Long-term color stability

-

Excellent UV and thermal resistance

Limitations:

-

Limited color brightness

-

Heavier particle structure may reduce gloss

Key Factors to Consider When Selecting Industrial Pigments

Choosing the right pigment involves balancing color performance with application-specific technical requirements. Here are the main factors to evaluate before making your choice.

1. Color Strength and Shade Matching

For coatings and plastics, consistency in color is crucial. The pigment must deliver strong tinting strength, allowing vibrant color even at low concentrations.

Using spectrophotometric color matching ensures uniformity across batches.

2. Heat Stability

Plastic manufacturing often involves high processing temperatures—especially for materials like polycarbonate, nylon, or ABS. Pigments must resist decomposition or discoloration during molding or extrusion.

If working with polymers such as polyolefin, PVC, or polycarbonate, ensure pigment compatibility with your base resin.

3. Light and Weather Resistance

Outdoor applications like automotive coatings or building materials require pigments with excellent UV and weather resistance. Organic pigments typically need stabilizers or UV absorbers to maintain brightness over time.

Inorganic pigments such as iron oxides or chromium oxides are preferred for environments exposed to sun and rain.

4. Chemical Resistance

Pigments may come into contact with oils, solvents, or cleaning chemicals, especially in industrial or packaging applications. Inorganic pigments are usually more resistant to chemical attack, while some organic pigments may require surface treatments to improve stability.

5. Opacity and Hiding Power

Opacity determines how well a pigment can mask the substrate. Titanium dioxide remains the top choice for opacity in both coatings and plastics. For transparent finishes, select pigments with smaller particle sizes that provide controlled translucency.

6. Dispersion and Processing Behavior

Poor dispersion can lead to clumps, streaks, or inconsistent color. Pigment dispersion is affected by particle size, surface treatment, and compatibility with dispersing agents or resin systems.

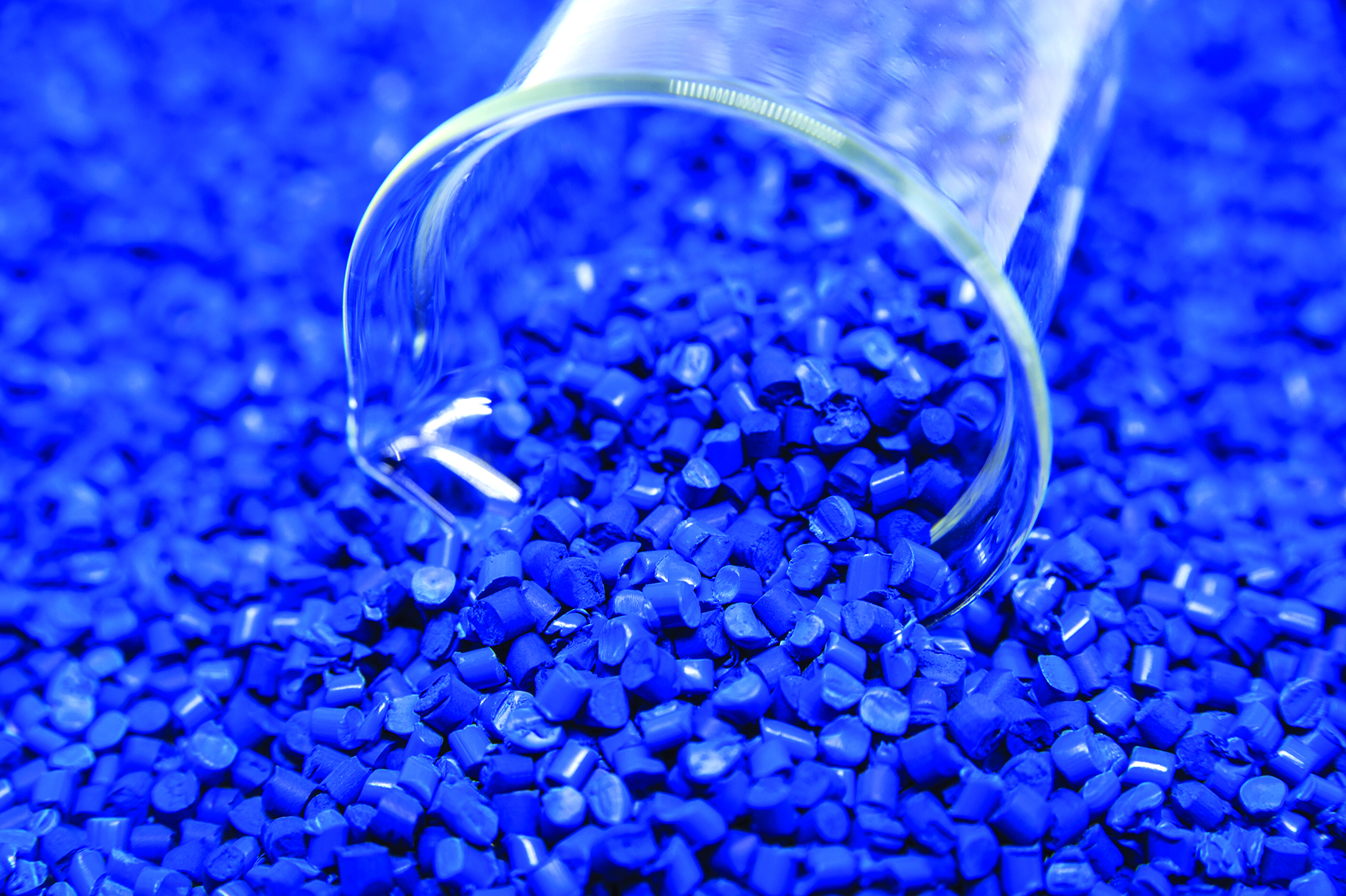

Masterbatch pigment systems help ensure uniform distribution in plastics and simplify processing.

7. Cost vs. Performance

Cost optimization doesn’t mean choosing the cheapest pigment—it means finding the best value for long-term durability and processing stability. Low-cost pigments may save money upfront but can cause fading, color inconsistency, or product rejections later.

Evaluate pigments not only by price per kilogram but by cost-in-use performance.

Industrial Pigments in Coatings

Pigments in coatings serve both decorative and protective roles. A well-selected pigment enhances appearance while contributing to surface protection against corrosion, UV, and wear.

Common Coating Applications:

-

Architectural coatings: Use TiO₂ and iron oxides for high opacity and UV durability

-

Automotive coatings: Use organic pigments for vivid colors, combined with inorganics for stability

-

Industrial and marine coatings: Inorganic pigments like zinc phosphate improve corrosion resistance

Performance Tip:

Always test pigment dispersion and film thickness to achieve the desired gloss, coverage, and durability before scaling up production.

Industrial Pigments in Plastics

Pigments for plastics must survive extrusion, molding, and UV exposure while maintaining mechanical properties.

Key Plastic Applications:

-

Packaging: Organic pigments for bright, appealing consumer colors

-

Engineering plastics (ABS, PC, Nylon): Heat-stable inorganic pigments

-

Films and fibers: Transparent organic pigments for clarity and brilliance

-

Outdoor products: UV-resistant inorganic pigments ensure long-lasting color

Tip: Always check pigment migration and compatibility to avoid bleeding or blooming issues in the final plastic product.

Environmental and Regulatory Considerations

Modern industries must also comply with global standards such as RoHS, REACH, and FDA. Lead, cadmium, and certain chromate pigments are being phased out in favor of eco-friendly alternatives.

Manufacturers now invest in non-toxic, heavy metal–free pigments with improved safety and sustainability. Waterborne coating formulations also require pigments with excellent dispersibility in aqueous systems.

Emerging Trends in Industrial Pigments

The pigment industry continues to evolve with advancements in technology and sustainability.

1. High-performance hybrid pigments:

Combining organic and inorganic chemistries to balance brightness with durability.

2. Functional pigments:

Pigments that not only provide color but also deliver special properties—like IR-reflective coatings, anti-corrosion effects, or self-cleaning surfaces.

3. Nano-pigments:

Smaller particle sizes enable improved transparency, gloss, and UV protection without sacrificing color strength.

4. Sustainability focus:

Growing demand for recyclable and biodegradable colorants in plastics aligns with global environmental goals.

Partnering with a Reliable Pigment Supplier

Partnering with a Reliable Pigment Supplier

Finding a dependable pigment supplier is as important as selecting the pigment itself. Look for companies that offer:

-

Consistent product quality and batch reproducibility

-

Technical support for formulation and dispersion

-

Regulatory compliance documentation

-

Long-term stability in supply chain and pricing

Working with a trusted supplier ensures not only pigment performance but also production reliability and cost control.

Conclusion

Choosing the right industrial pigment for coatings and plastics requires careful consideration of color performance, processing stability, and environmental compliance.

By understanding the differences between pigment types—organic and inorganic—and evaluating key performance factors such as heat resistance, UV stability, and dispersion, manufacturers can achieve both aesthetic and functional excellence.

In a competitive market, high-quality pigments are more than colorants—they’re the foundation of durable, reliable, and beautiful products. Partner with a trusted pigment supplier, and your coatings and plastics will stand out with lasting brilliance and performance.

Partnering with a Reliable Pigment Supplier

Partnering with a Reliable Pigment Supplier