Understanding the Role of Pigments in Modern Coatings

In the coatings industry, pigments are more than just colorants — they are critical components that determine a coating’s appearance, protection, and long-term stability. A well-formulated pigment system not only defines the color and gloss but also strengthens the coating’s resistance to sunlight, chemicals, and mechanical wear.

As Your Reliable Pigment Partner, Fineland Chem continues to explore how pigment technology contributes to coating performance and helps customers achieve both aesthetic brilliance and lasting protection.

1. Pigments and Coating Durability

The durability of a coating largely depends on how pigments interact with the binder and external environmental factors. Pigments protect the coating by:

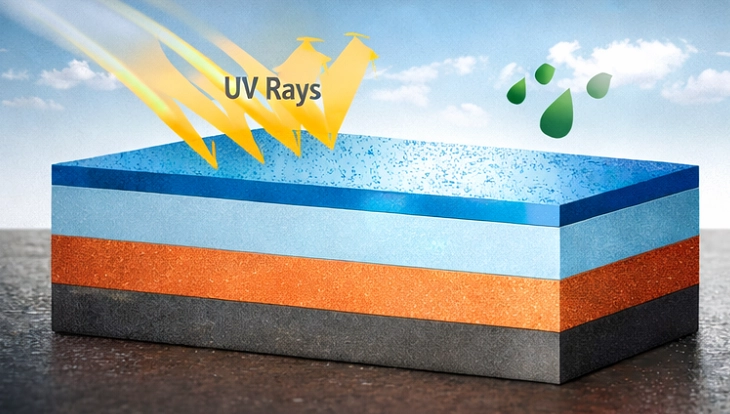

a. Shielding Against UV Radiation

Certain pigments, especially inorganic types such as titanium dioxide and iron oxides, reflect or absorb ultraviolet light. By doing so, they protect the binder from UV degradation — a common cause of chalking, fading, and cracking.

b. Enhancing Weather and Chemical Resistance

High-performance organic pigments, like Pigment Red 254 (PR254) and Pigment Blue 15:6, are engineered with stable molecular structures that resist chemical breakdown. These pigments ensure color retention and prevent premature aging under sunlight, humidity, or industrial conditions.

c. Improving Heat Stability and Corrosion Resistance

In protective and industrial coatings, pigments with metal oxide or complex inorganic compositions act as thermal barriers. They reduce heat buildup, limit oxidation, and increase the coating’s lifespan even in harsh environments.

2. Pigments and Gloss Development

Gloss is one of the key indicators of a coating’s visual quality. Pigments influence gloss in multiple ways:

a. Particle Size and Dispersion

Uniformly dispersed pigments with fine particle size help create a smooth surface, which reflects light evenly and results in higher gloss. Poor dispersion, by contrast, scatters light irregularly and reduces gloss.

b. Refractive Index and Transparency

Pigments with a refractive index close to that of the binder — such as certain organic reds and blues — enhance transparency and depth, giving coatings a polished, glossy finish. Highly opaque pigments like titanium dioxide, meanwhile, provide a brilliant but less transparent gloss.

c. Surface Treatment and Resin Compatibility

Modern pigment surface treatments improve wetting and compatibility with different resin systems, reducing surface defects and helping maintain gloss stability during aging or exposure.

3. Choosing the Right Pigment Type

Selecting pigments depends on the performance and appearance requirements of the coating system:

| Coating Type | Recommended Pigment Characteristics | Example Pigments |

|---|---|---|

| Automotive Coatings | High chroma, lightfastness, and weather stability | PR254, PB15:6, PV23 |

| Architectural Coatings | UV protection, opacity, and cost efficiency | Titanium dioxide, iron oxides |

| Industrial Coatings | Chemical resistance and thermal stability | PR177, chromium oxide green |

| Decorative Coatings | Transparency and brilliance | Phthalocyanine blue, quinacridone red |

For additional understanding of pigment classification and color mechanisms, refer to the internal knowledge article “Pigment Theory and Color Science Training Session.”

4. The Role of Dispersion in Gloss and Durability

Proper pigment dispersion is vital for maximizing coating performance. During dispersion, pigments are broken down and stabilized within the binder system to achieve consistent particle distribution.

Key stages include:

-

Wetting – Resin surrounds pigment particles, reducing surface tension.

-

Deagglomeration – Shear forces separate pigment clusters into smaller units.

-

Stabilization – Dispersants prevent re-agglomeration, ensuring long-term suspension stability.

A well-dispersed pigment not only improves color uniformity and gloss, but also contributes to film strength and resistance against environmental damage.

5. Balancing Gloss and Durability Through Formulation Design

Achieving the ideal combination of gloss and durability requires a balanced pigment formulation.

High-gloss coatings typically use fine organic pigments for brightness, supported by inorganic pigments for stability and UV protection. Conversely, matte or weather-resistant coatings may favor higher pigment volume concentrations and surface-modified particles.

This balance allows formulators to tailor coatings for specific functions — from automotive finishes requiring deep gloss and long-term color retention to industrial coatings focused on protection and corrosion control.

Summary

Pigments determine not only the color of a coating but also its ability to resist environmental stress, maintain gloss, and preserve film integrity. Through careful pigment selection, optimized dispersion, and formulation design, coatings can achieve both visual quality and functional durability.

For detailed pigment examples and related performance characteristics, see our product page for Pigment Red 254.