Pigment Red 254 (C.I. PR254) is a high-performance organic red pigment widely used in plastics, coatings, and printing inks. Known for its excellent color strength, bright bluish-red shade, and outstanding fastness properties, PR254 has become a preferred choice for industrial manufacturers seeking both visual impact and long-term durability.

As regulatory requirements tighten and supply chains continue to evolve, buyers are increasingly focused not only on color performance but also on consistency, compliance, and substitution feasibility. This article provides a comprehensive overview of Pigment Red 254, including its key properties, application distribution, competitive performance comparison, and regulatory considerations—helping formulators and procurement teams make informed decisions.

What Is Pigment Red 254?

Pigment Red 254 belongs to the DPP (Diketopyrrolopyrrole) pigment family, which is recognized for superior performance compared to conventional organic red pigments. Its molecular structure contributes to high tinting strength, excellent lightfastness, and resistance to heat and migration.

Compared with traditional monoazo or diazo red pigments, PR254 offers improved durability, making it suitable for demanding industrial applications where color stability is critical.

👉 Learn more about pigment classification in our guide:

Organic Pigments vs. Inorganic Pigments

Key Performance Properties of Pigment Red 254

Pigment Red 254 is valued for a balanced combination of optical and physical performance:

-

High Color Strength – Enables reduced pigment dosage while maintaining vivid coloration

-

Excellent Lightfastness – Suitable for both indoor and outdoor applications

-

Good Heat Resistance – Performs well in standard plastic processing temperatures

-

Low Migration & Bleeding – Especially important for plastic and coating systems

-

Clean, Bright Shade – Produces a modern bluish-red tone favored in many markets

These properties make PR254 an ideal pigment for manufacturers seeking long-term color reliability without compromising processing efficiency.

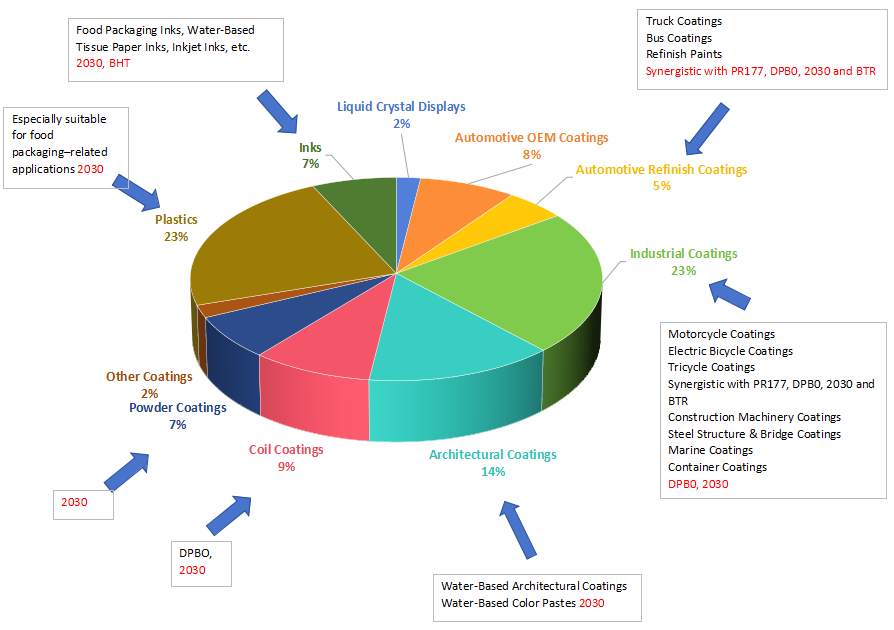

Application Distribution and Typical Uses

Pigment Red 254 is used across a wide range of industrial sectors:

Plastics

Commonly applied in:

-

Polyolefins (PP, PE)

-

PVC

-

ABS and PS

Its migration resistance and color stability make it suitable for both rigid and flexible plastic products.

👉 Related reference:

Pigments for Plastic Applications

Coatings

PR254 is widely used in:

-

Industrial coatings

-

Powder coatings

-

Automotive and refinish coatings

Its high chroma and weather resistance allow coatings to retain visual appeal under long-term exposure.

👉 See also:

How to Improve Pigment Opacity in Coating Systems

Printing Inks

In solvent-based and UV-curable inks, PR254 delivers:

-

High transparency or opacity control

-

Excellent dispersion

-

Stable shade reproduction

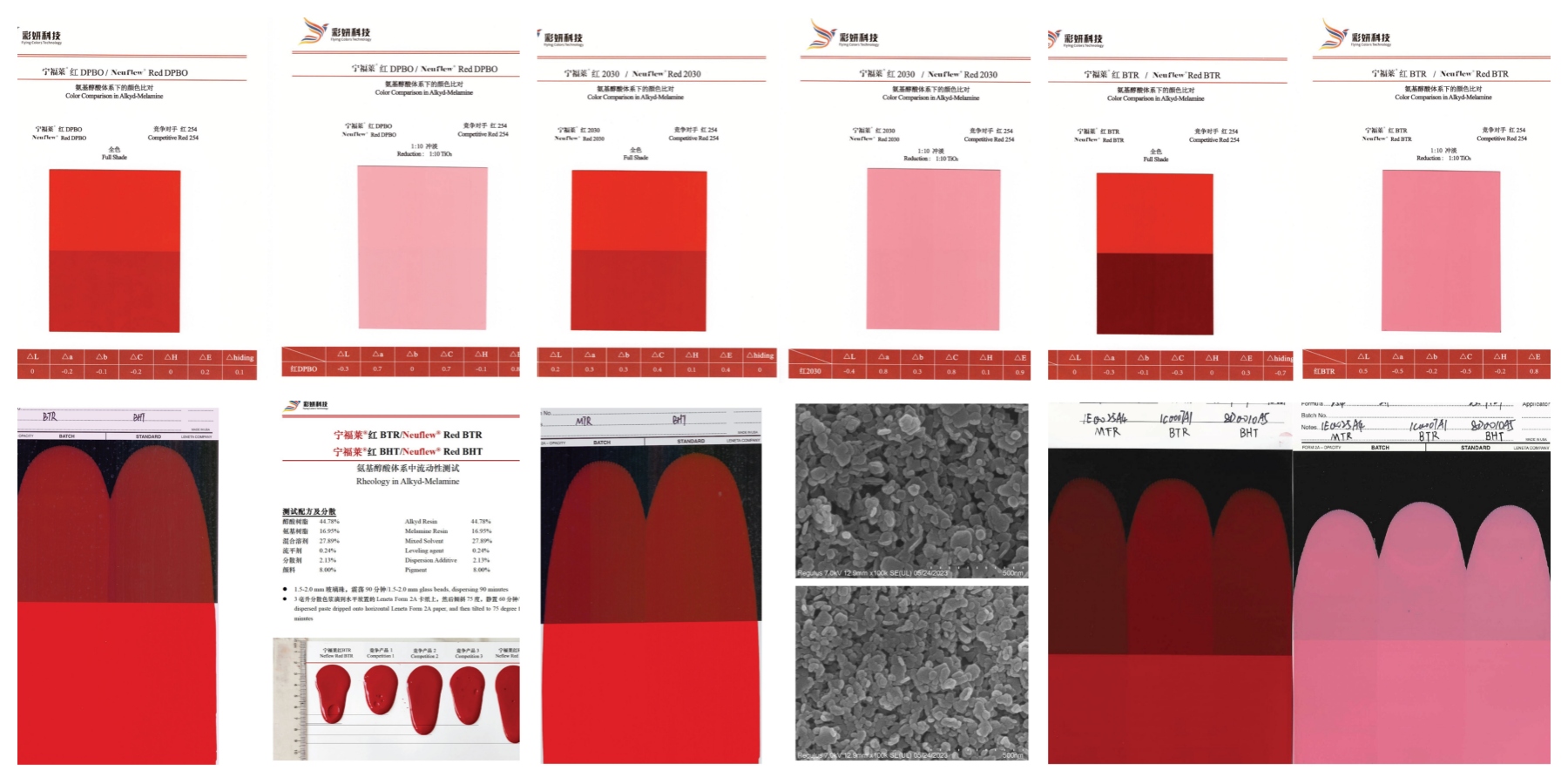

Competitive Performance Comparison (Drawdown Test Results)

To evaluate real-world performance, Pigment Red 254 from Fineland Chem was tested against several widely used competitor grades using standardized drawdown paper under identical formulations.

The drawdown results demonstrate:

-

Comparable or higher color strength

-

Clean and consistent shade matching

-

Uniform dispersion without visible agglomeration

-

Smooth film appearance with no surface defects

These results confirm that Fineland Chem’s PR254 can function as a direct replacement for mainstream commercial grades, allowing customers to switch suppliers without reformulation risks.

Note: All drawdown images shown below are produced under controlled laboratory conditions and are provided for reference purposes.

Suggested image alt text:

-

Pigment Red 254 drawdown comparison on coated paper

-

PR254 color strength comparison versus competitor pigments

-

Pigment Red 254 dispersion performance drawdown test

Regulatory Compliance and Safety Considerations

Pigment Red 254 is compliant with major international regulations commonly required for industrial pigments, including:

-

REACH compliance (EU)

-

RoHS compliance

-

EN71-3 (relevant for consumer-related plastic applications)

This makes PR254 suitable for export-oriented manufacturers serving global markets.

| Relevant Regulations | Compliance Status |

| Directive 2009/48/EC on the safety of toys | √ |

| Regulation(EU)No. 10/2011 on Plastic contact with Food | √ |

| Resolution AP 89-1 | √ |

| Directive 94/62/EC on packaging and packaging waste | √ |

| EN 7l-3 Part 3 Migration value on certain elements | √ |

| EN71-9:2007 Safety of Toys(Part9); EN71-12:2013 Part12 | √ |

| Regulation (EC) No. 2023/2006 food contact | √ |

| Resolution AP(2002)1/ Resolution AP(2004)lon paper and board contact with food | √ |

| FDA 21 CFR 178.3297. Up to 1%, Condition B-H | √ |

| ASTM-F963-1l Standard Consumer Safety Specification for Toy Safety | √ |

| CONEG Resolution | √ |

| GB-9685-2106 | √ |

| JHOSPA | √ |

Competitive Performance Comparison

In addition to standard technical data, visual performance comparison plays a critical role in pigment evaluation. Based on multiple drawdown tests conducted on coated paper using identical formulations and processing conditions, Pigment Red 254 demonstrates color strength, shade consistency, and dispersion behavior that are fully comparable to, and in some cases superior to, mainstream competitor grades available on the market.

The attached drawdown samples clearly illustrate that Fineland Chem’s PR254 can serve as a reliable drop-in alternative for established brands, offering stable coloration, clean hue, and uniform film appearance without formulation adjustments. These results provide strong practical evidence for customers seeking qualified replacements or cost-performance optimization.

Why Choose Fineland Chem’s Pigment Red 254?

At Fineland Chem, Pigment Red 254 is produced with strict quality control and batch-to-batch consistency. Our focus is not only on color performance but also on supply reliability and technical support.

Key advantages include:

-

Stable quality suitable for long-term production

-

Competitive performance versus leading brands

-

Technical assistance for formulation and substitution

-

Responsive support for B2B customers

👉 Product page reference:

Pigment Red 254 – Fineland Chem

Frequently Asked Questions (FAQ)

1. Is Pigment Red 254 suitable for plastic applications?

Yes. PR254 is widely used in PP, PE, PVC, and engineering plastics due to its good heat resistance and low migration properties.

2. Can Pigment Red 254 replace other commercial red pigments?

Based on drawdown and formulation tests, PR254 can serve as a direct replacement for many mainstream DPP red pigments without requiring formulation changes.

3. Is Pigment Red 254 compliant with EU regulations?

Yes. PR254 complies with REACH and other commonly required industrial pigment standards. Specific documentation can be provided upon request.

4. Does Pigment Red 254 work in coating systems?

PR254 performs well in industrial and powder coatings, offering excellent color strength and weather resistance.

5. How can I evaluate Pigment Red 254 for my formulation?

Customers are encouraged to conduct drawdown or pilot-scale testing. Technical support is available to assist with evaluation and substitution guidance.